For the last ten years, PC makers have been using the tin-based solder process, instead of the former lead-based process due to environmental concerns. Yet since the current tin-based process requires “extremely high temperatures consuming more energy and adding significant stress on components,” an improved process was needed.

Recently, Lenovo “announced a new patent-pending Low Temperature Solder (LTS) process developed to improve PC manufacturing by conserving energy and increasing reliability.”

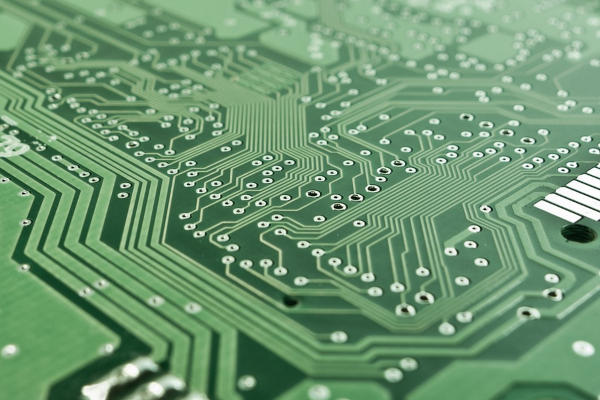

Typical PC manufacturing, results

“in standard electronics assembly using surface mount technology (SMT), the solder and flux mixture is first printed on the face of the circuit board. The components are then added and heat is applied to melt the solder mixture, securing and connecting the components to the board.”

The new LTS process, the maximum solder heat is 180 degrees Celsius, a reduction from previous methods by 70 degrees. Lenovo also uses basically the same materials and equipment in the new LTS process and therefore the costs remain the same. Lenovo is using the new LTS process in the current manufacture of the ThinkPad E series and the 5th generation X1 Carbon.

The new LTS process will significantly reduce carbon emissions and provide a

“50% decrease in printed circuit board warpage and a reduction in defective parts per million during the manufacturing process.”

Lenovo, a leader in innovation, technology and sustainability, has already agreed in 2018, “to offer the new procedure for use on an industry-wide basis free of charge.”